Carbon Crystal Panel-Technical Name: "Bamboo Charcoal Co-extruded Decorative Panel" (also known as "Bamboo Charcoal Fiber Board")

This is a wood-plastic composite board manufactured through high-temperature extrusion, incorporating bamboo charcoal powder, calcium powder, PVC resin, and various additives. Its unique layered structure and functional properties distinguish it in the decorative building materials sector. Below is an analysis across four dimensions: structure, performance, manufacturing, and applications.

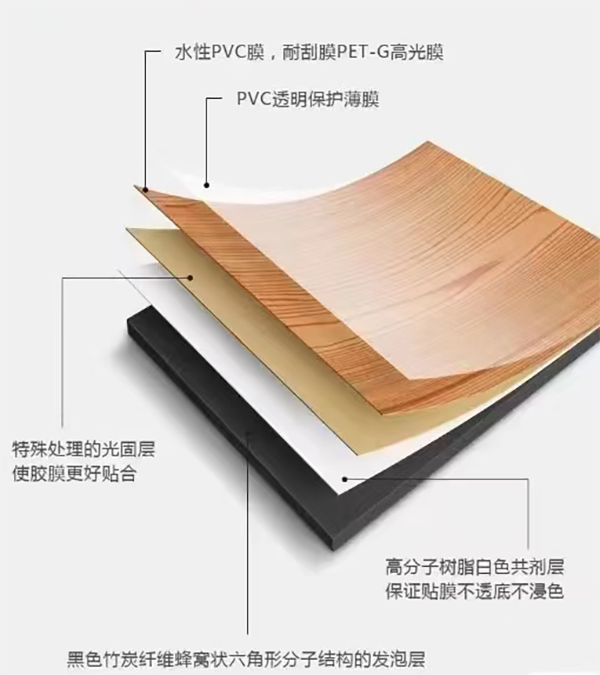

I. Structural Analysis of Bamboo Charcoal Board

The board comprises seven functional layers:

Protective Surface Film: Transparent PVC film provides lightweight, durable moisture and scratch resistance.

Decorative Film Layer: Customizable with water-based PVC, metal brush, PP scratch-resistant, matte stone, PET mirror, or PET-G high-gloss finishes, offering wood, fabric, stone, metallic, or glass-like textures.

UV-Adhesive Layer: Ensures seamless bonding between layers via light-curing technology.

PP Co-extruded Skin Layer: Enhances impact resistance and surface uniformity.

Core Material Layer: A hexagonal honeycomb structure formed by bamboo charcoal powder, resin, and polymers under high heat, ensuring strength and stability.

II. Performance Advantages

Aesthetic Versatility:

Dual-sided co-extrusion with cold glue/PUR hot-melt adhesive enables wood, stone, metallic, and other finishes for personalized designs.

Rapid Installation & Cost-Efficiency:

Customizable within 3–7 days; modular installation suits fast-track projects.Durability & Protection:

High hardness, wear/scratch resistance, B1-grade flame retardancy, and easy-to-clean surfaces resist warping/aging.Design Flexibility:

Cuttable, groovable, and bendable for wall corners, columns, or curved installations.

III. Installation Guidelines

Substrate Preparation:

Ensure walls are flat (≤3mm/㎡ variance), crack-free, and debris-free.Panel Fixing:

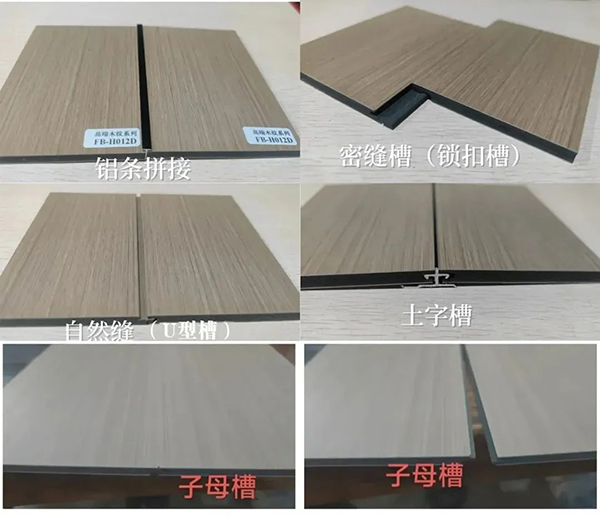

Apply structural adhesive in perimeter lines + "W"-pattern (1cm thickness). Align with a level and secure via rubber mallet.Joint & Edge Treatment:

Seams: Use interlocking grooves (T-slot/mother-child slot) or metal trims.

Corners: Employ edge trims, curved/right-angle bending.

IV. Applications

Residential: Feature walls, wainscoting, ceilings.

Commercial: Offices, hotels, retail spaces.

Special Environments: Kitchens, bathrooms (humidity-resistant), corridors (fire-safe).

As an eco-friendly innovation, bamboo charcoal boards merge structural ingenuity, aesthetic diversity, and functional adaptability, positioning them as a rising star in modern construction. Ongoing advancements promise broader applications, redefining design possibilities.

Scan to follow & learn more